[

14

]

The Port of Baltimore

■

January/February 2014

Environmental Stewardship at the Port of Baltimore

>

>

>

Green

Port

BY NANCY MENEFEE JACKSON

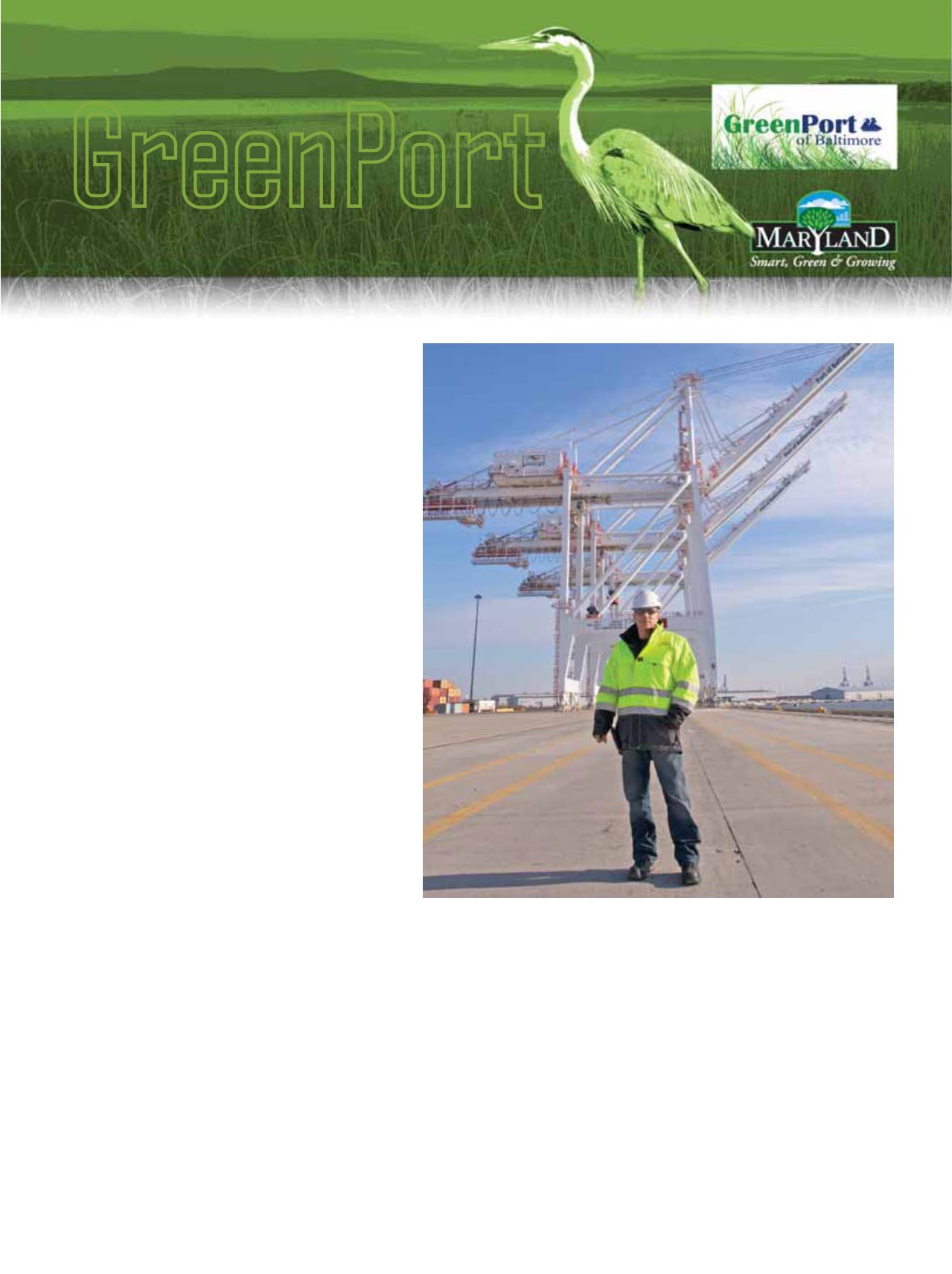

Ports America

Chesapeake Crane &

Engineering Manager

Patrick Howell

has noted that the

electric-powered

Seagirt cranes reduce

the carbon footprint

while increasing

production.

KATHY BERGREN SMITH

Energy Saved

with

Seagirt’s Fast-working

Electric Cranes

F

our massive, electric-powered cranes now

operating at the Seagirt Marine Terminal

yield such increases in productivity that they

result in significant energy savings.

The cranes do not burn fuel; they use heavy-duty

electric cables to connect directly to the power grid,

running on 13,200 volts — significantly higher than

the older cranes. The higher the voltage, the less

demand on the power grid.

But the cranes’ real efficiencies lie in their ability

to unload ships faster, reducing the amount of time

that ships are idling at the berth, as well as reducing

fuel usage on equipment being used to unload the

vessels.

“When the crane is fully boomed up, it is just

over 400 feet tall or roughly the height of a 40-story

building,” said

Patrick Howell

, Crane & Engineering

Manager with Ports America Chesapeake.

With a working height of 110 feet, the older

cranes sometimes struggle to get across the boxes

stacked on the larger ships calling on Baltimore —

and this is before the gigantic post-Panamax ships

begin arriving in 2015. The new cranes add 30 feet

to the capable working height and can reach across

a ship where the containers are stacked 22 wide, as

opposed to 18 wide with the old cranes.

“We were limited with our outreach and our

working height on anything bigger than an 18-wide

ship,” Howell said, noting that the newer 14,000

TEU ships can have a draft of 50 feet and reach 22

containers wide. “They’re almost double the size of a

typical ship currently coming into Baltimore.”

Even more significantly, the new cranes can pick

up two containers at once. The older cranes could,

too, but only if the containers were not packed to

their maximum weight. A container can hold up

to 67,800 pounds, or roughly 34 short tons. Two

containers would weigh 68 tons, but the capacity of

the older cranes is only 50 tons.

“Capacity is a big deal, because the boxes are

coming in heavier and are regularly exceeding the

50-ton capacity we had with our older cranes,”

Howell said. “Now we can do two 34-short-ton

containers at once. In almost all scenarios, we’ll be

able to twin pick, which helps us to become more

efficient while using less energy. The new cranes

have given us the opportunity to help reduce our

carbon footprint in the Baltimore community while

also increasing our capabilities and production to

make the Port a more attractive option for current

and potential customers.”